Huvitz Patternless Edger HPE-910

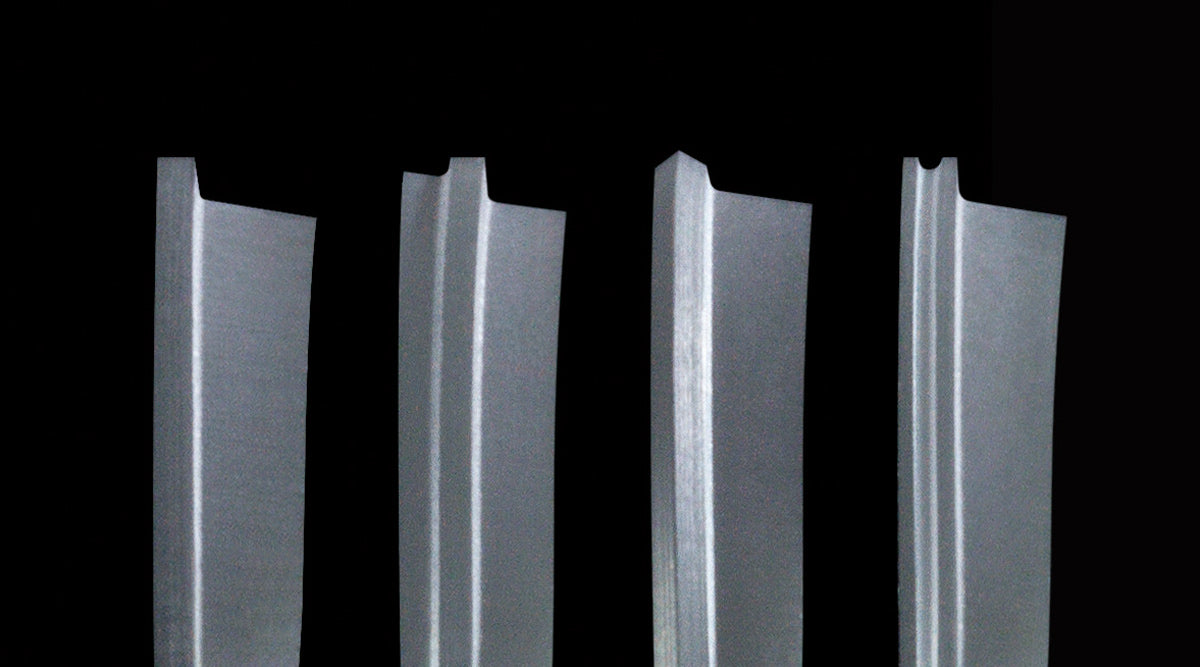

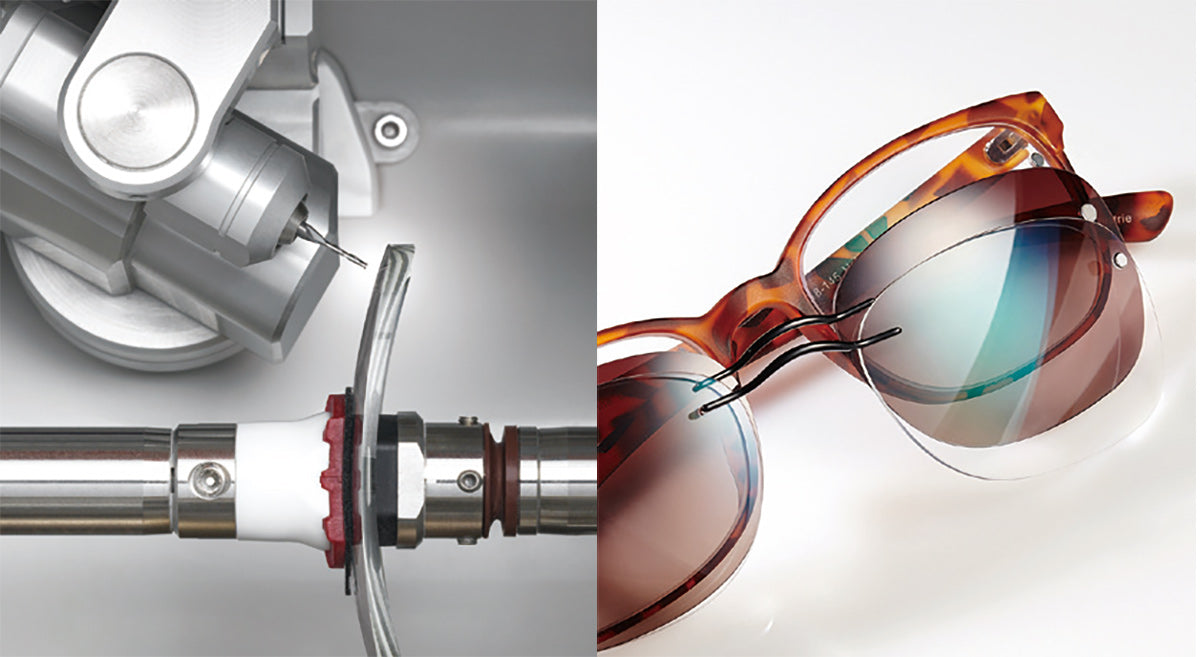

The Huvitz HPE-910 edger offers advanced features designed to enhance efficiency and precision in lens processing. It boasts a built-in drill with exceptional durability, significantly reducing processing time by over 50%. The step bevel feature ensures perfect fitting with seven types and five edge styles, catering to diverse preferences. Equipped with a more powerful wheel motor and flexible adaptive chuck, this edger can effortlessly handle high-curve and various coating lenses. It excels in processing complex tasks, including variable asymmetric adjustments for height, such as Semi-U, Asymmetric, Partial Grooving/Beveling, Hybrid Grooving, and Dual Grooving. Additionally, its concave shape grooving and improved retouch capabilities further enhance its performance and versatility.

Engineered for efficiency and precision, this reference outlines the optimal HPE-910 edger settings for various lens materials, empowering optical professionals to deliver consistently flawless results. By following these tailored parameters, you ensure superior lens protection, extend the life of your equipment, and maximize productivity—helping your business maintain the highest standards of quality and service.

| Product Type | Voltage | Step Bevel | Built-in Drill | Wheel Type | Vacuum I/F |

|---|---|---|---|---|---|

| HPE-910(XD) | 110V / 220V | ✔ | ✔ | RPA | ✔ |

| HPE-910(X) | 110V / 220V | ✔ | x | RPA | ✔ |

| HPE-910(D) | 110V / 220V | x | ✔ | RPA | ✔ |

| HPE-910(N) | 110V / 220V | x | x | RPA | ✔ |

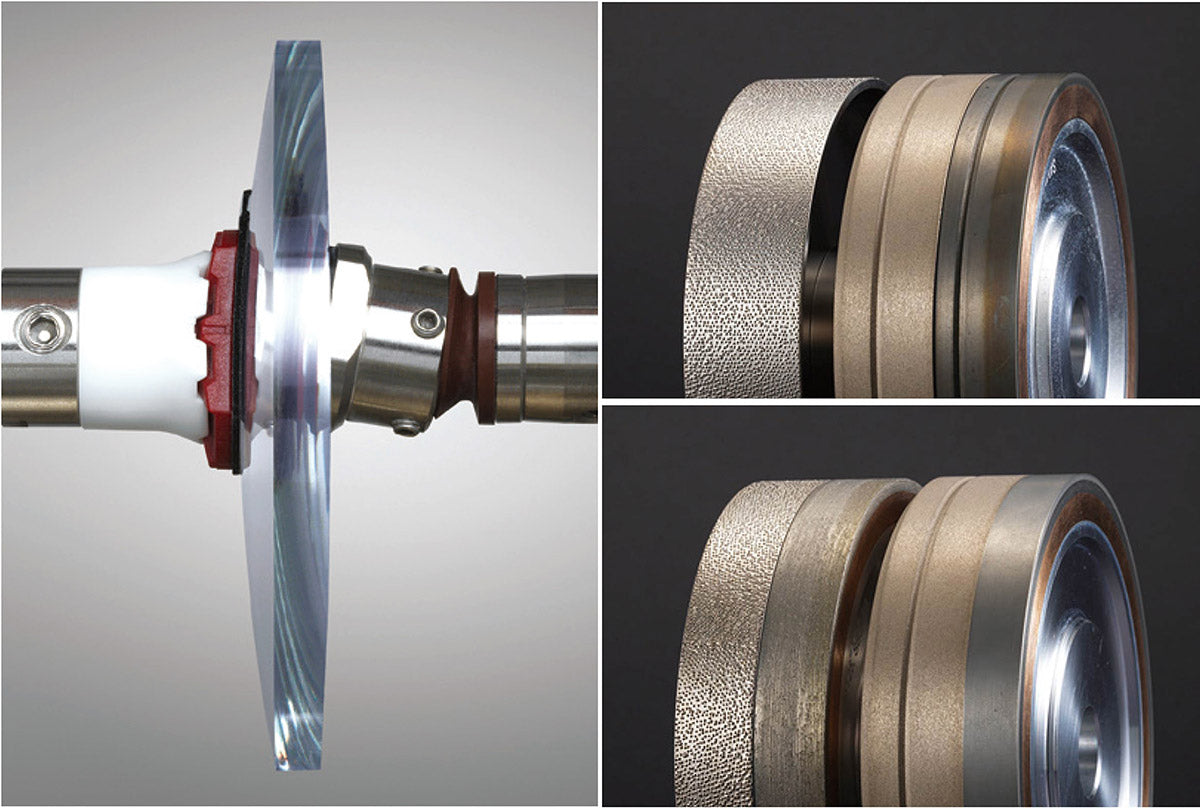

The configuration of the All Plastic diamond wheels allows for beveling of all materials, including CR39, polycarbonate, Trivex, and Hi-index. Additionally, a special configuration for glass can be requested. The high polishing function ensures high-quality finishes. With its multidirectional articulated terminal adaptable to the lens surface and its special program for hydrophobic lenses, the equipment ensures a perfect grip, preventing slips and improving accuracy in the beveling process.

The HPE-910 offers 35 types of finishing and positioning combinations to achieve a perfect fit between the frame and the lens.

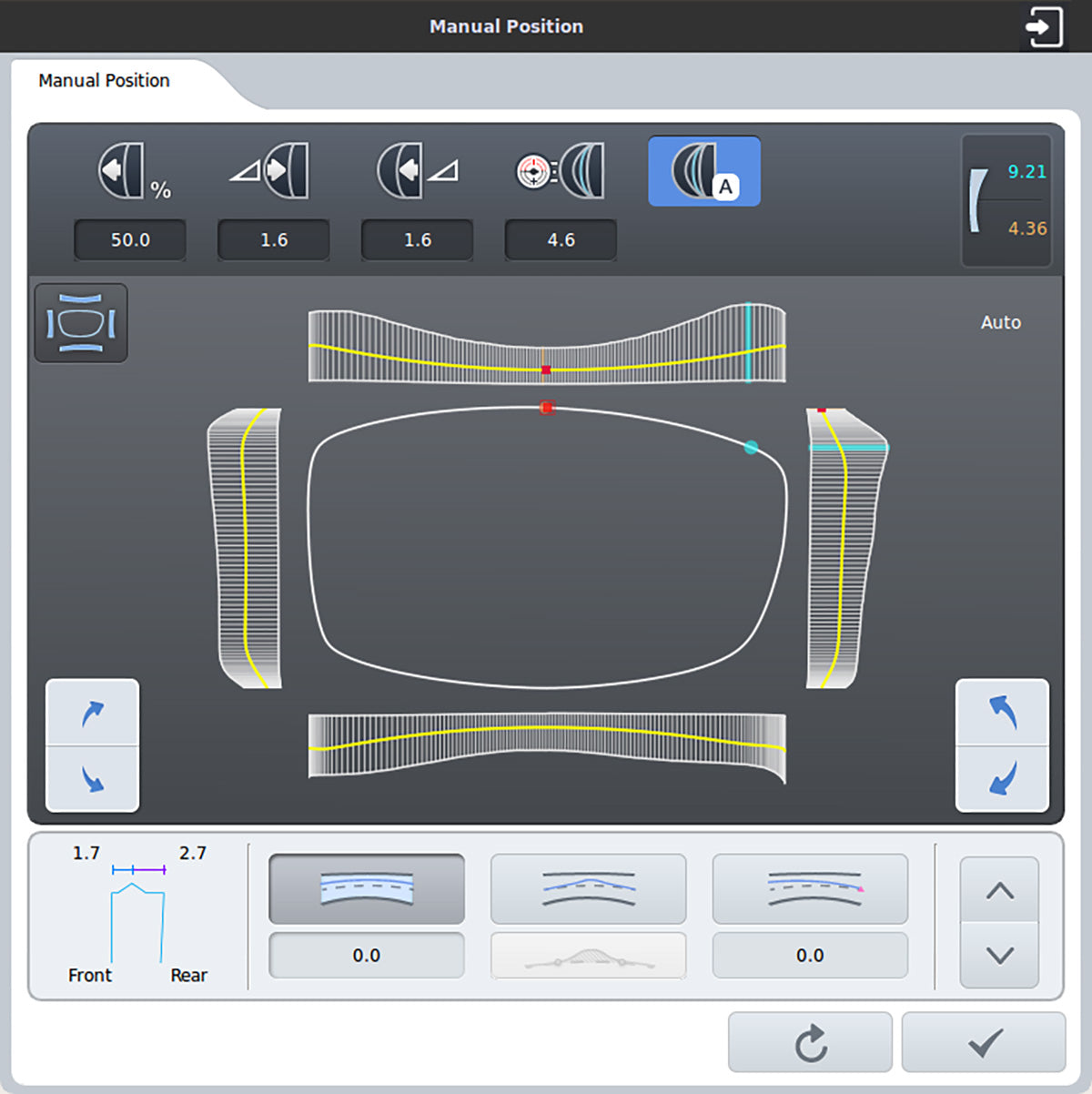

The manual finishing position editor allows you to easily select the most suitable position for your frame in manual mode. For conventional frames and lenses, it is convenient to process them using the automatic position mode.

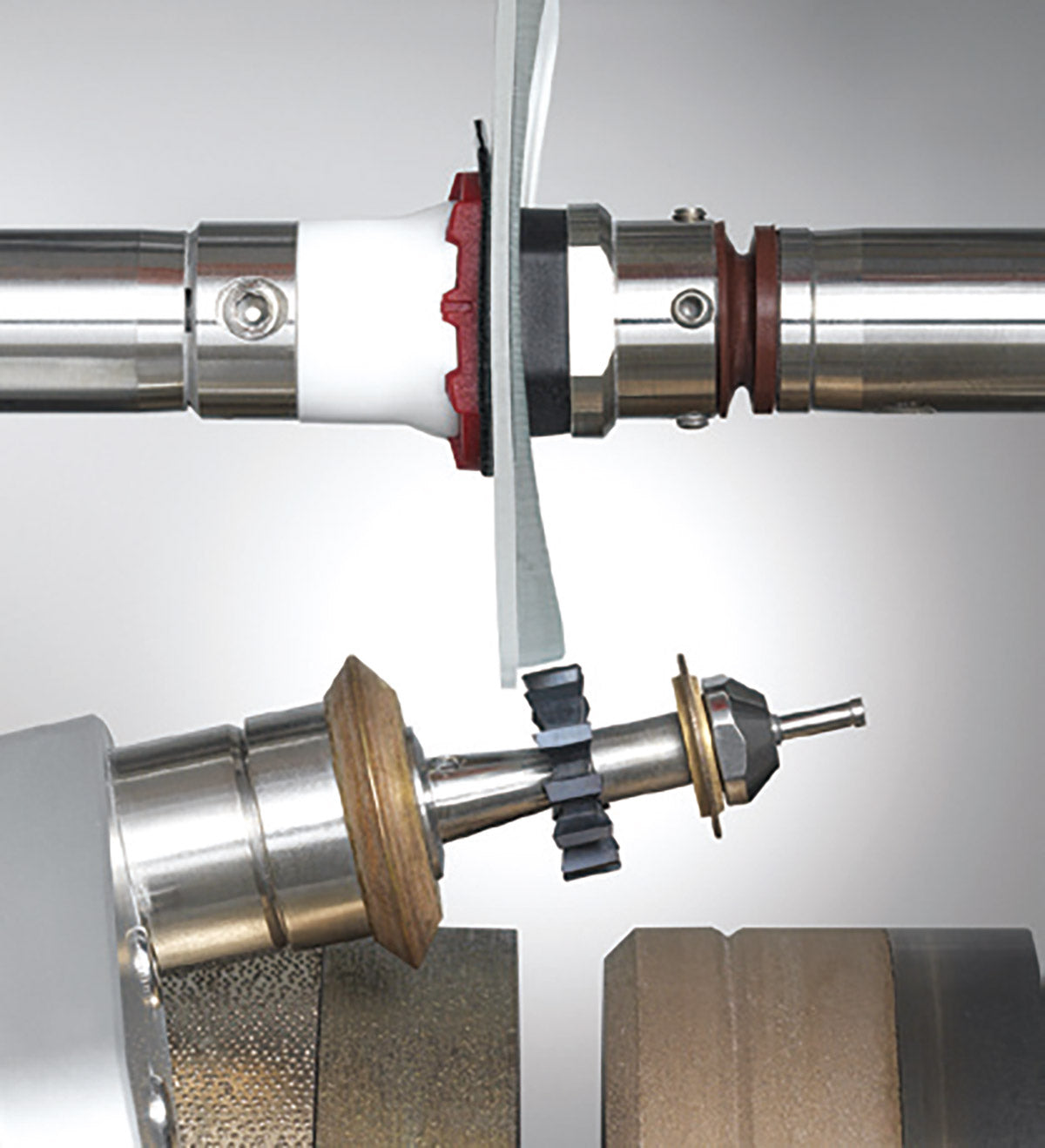

The grooving arm, safety bevel, and stepped bevel cutter are connected to a powerful motor, enabling precise finishing of special frames.

The powerful drilling arm features automatic variable inclination from 0 to 30 degrees, reducing drilling times by 50%.

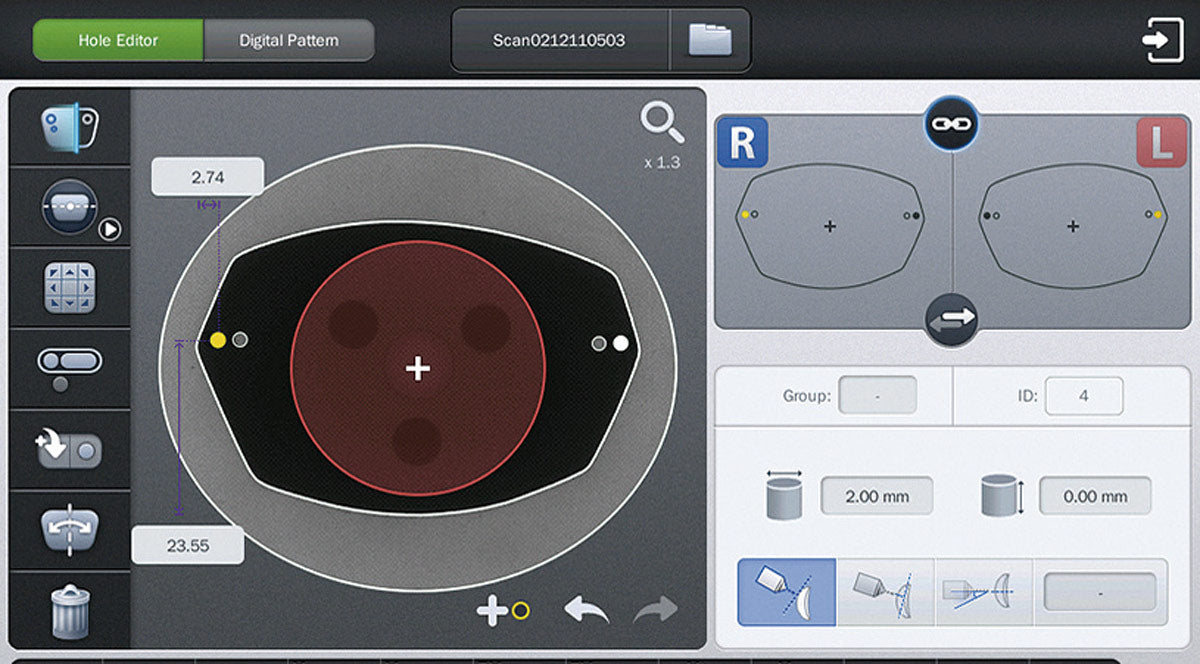

In hole editing mode for rimless frames, users can manipulate the background image of the scanned demo lens. This facilitates easy addition or correction of holes, slots, or notches, supporting both square and circular shapes. Users of the system have the flexibility to select drilling positions based on parameters such as center/edge/box edge or the distance from a specific hole. Additionally, they can import and utilize previously saved drilling information, allowing for the registration of drilling patterns on presets. This functionality streamlines the editing process, enhancing efficiency and productivity.

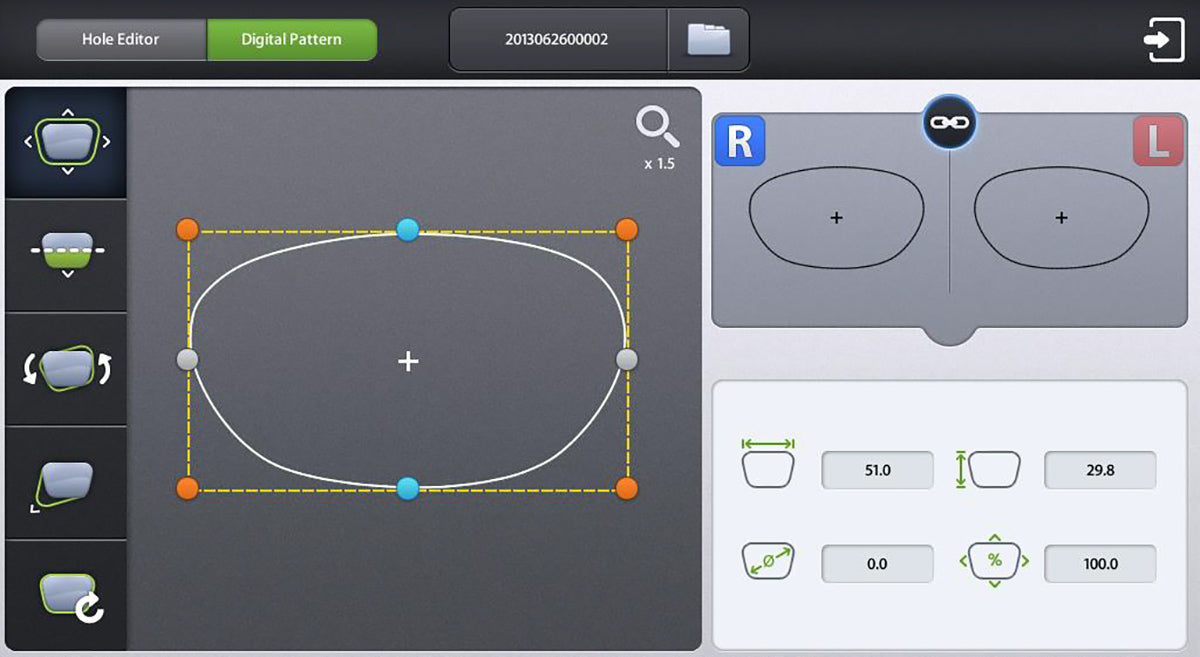

The shape editor provides the ability to adjust the size in specific areas, allowing for the creation of customized designs with greater precision. This functionality is particularly useful for digitally stretching the shape and ensuring an optimal fit in the near zone of bifocal and multifocal lenses.

It facilitates the assembly of a wide variety of special and sports lenses.

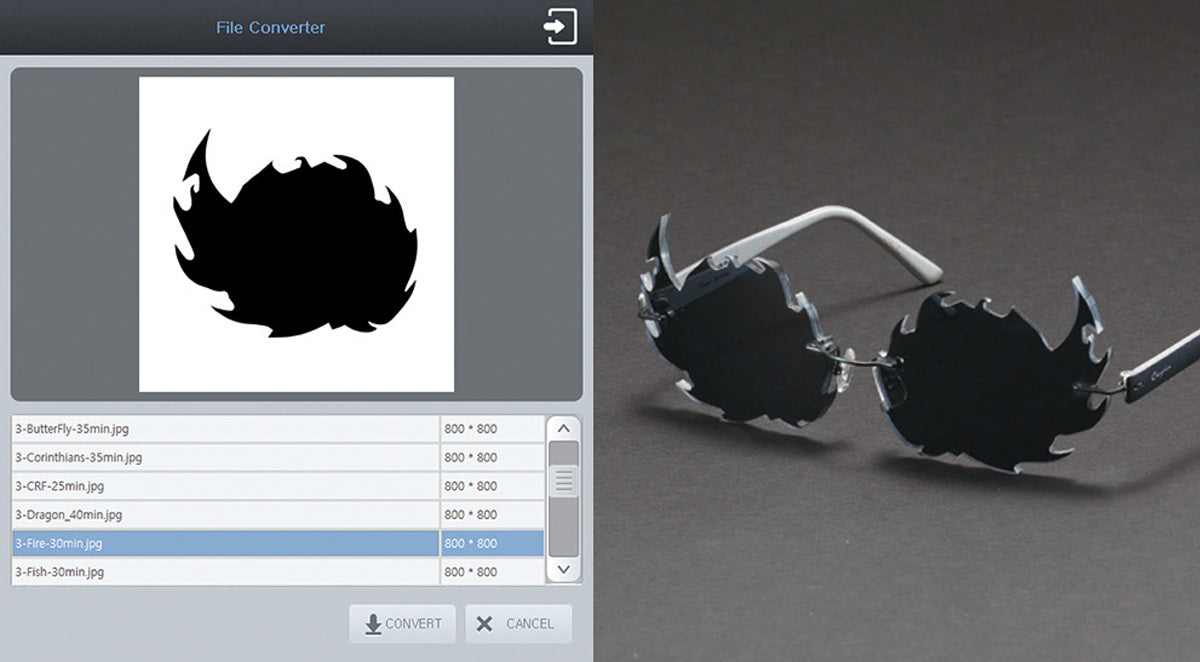

The OMA file conversion provides an efficient solution for processing special and rimless glasses. By allowing immediate processing without the need to edit the drilling design, this process streamlines production and enhances precision. The files provided by the frame manufacturer can be directly imported into the equipment via an SD card, simplifying the workflow and ensuring seamless integration into the production of custom lenses.

Choose any configuration, and Huvitz guarantees high-quality performance. You can make different combinations: HPE-910 with the automatic blocker HAB-910; HPE-910 with the tracer HFR-8000 and the manual blocker HMB-8000 and finally, the HPE-910 with the tracer HFR-8000 and the digital blocker HBK-410.

Click here to see the brochure

Click here to see the manual

| Lens Material | Plastic, Polycarbonate, High index plastic, Glass, Trivex |

| Edging Type |

Bevel, Groove, Rimless, Mini bevel, Partial bevel, Partial groove, Dual groove, Hybrid groove, Asymmetric bevel, Semi-U bevel, Step bevel* |

| Edging Position | Front %, Front mm, Rear mm, Base curve, Auto, Manual (with 2D simulation and 3D preview) |

| Edging Options | Polishing, Saftety bevel, Safety mode |

| Built-in Drilling | Hole, Slot, Notch, Scan & Cut shape, Chemistrie Clip |

| Functions | Job manager, Digital pattern, Hole editor, Asymmetric bevel editor, Scan & Cut shape editor, Step bevel editor, OMA import/export, CAD export, DCS/OMA compatibility, Retouch mode (Normal, Drill-only, All) |

| Utilities |

LCD tilting Automatic edging room door Edging room illumination SD card storage (Memory card included) Barcode reader interface, Vacuum interface |

| Edging Size |

Max : 3.5in / 90mm Min : Flat Edging : 0.7in / 18.5mm (without safety bevel) Bevel Edging : 0.78in / 20mm (without safety bevel) |

| Display | 9.7 inch color TFT LCD(1024x768) with touch screen |

| Dimensions | 540(W) x 472(D) x 580(H)mm 51.2kg (110V), 50.2kg (220V) |

| Power Supply | AC 100~120V / AC 200~240V 50/60Hz |

| Power Consumption | 1400VA |

| Lens Material | Plastic, Polycarbonate, High index plastic, Glass, Trivex |

| Edging Type |

Bevel, Groove, Rimless, Mini bevel, Partial bevel, Partial groove, Dual groove, Hybrid groove, Asymmetric bevel, Semi-U bevel, Step bevel* |

| Edging Position | Front %, Front mm, Rear mm, Base curve, Auto, Manual (with 2D simulation and 3D preview) |

| Edging Options | Polishing, Saftety bevel, Safety mode |

| Built-in Drilling | Hole, Slot, Notch, Scan & Cut shape, Chemistrie Clip |

| Functions | Job manager, Digital pattern, Hole editor, Asymmetric bevel editor, Scan & Cut shape editor, Step bevel editor, OMA import/export, CAD export, DCS/OMA compatibility, Retouch mode (Normal, Drill-only, All) |

| Utilities |

LCD tilting Automatic edging room door Edging room illumination SD card storage (Memory card included) Barcode reader interface, Vacuum interface |

| Edging Size |

Max : 3.5in / 90mm Min : Flat Edging : 0.7in / 18.5mm (without safety bevel) Bevel Edging : 0.78in / 20mm (without safety bevel) |

| Display | 9.7 inch color TFT LCD(1024x768) with touch screen |

| Dimensions | 540(W) x 472(D) x 580(H)mm 51.2kg (110V), 50.2kg (220V) |

| Power Supply | AC 100~120V / AC 200~240V 50/60Hz |

| Power Consumption | 1400VA |

English Version / Introduction

English Version